Introduction to RKS.23 0411 Slewing Ring Bearings

RKS.23 0411 is indeed a four point contact ball slewing bearing that is specifically engineered to manage axial, radial, and moment loads concurrently. This design allows for versatile applications across various industries, where machinery and equipment demand precise rotation and the ability to withstand significant loads from different directions. Its capability to handle multiple types of loads makes it a versatile solution for a wide range of industrial and mechanical systems, ensuring stability, smooth operation, and durability.

images source:https://rigiabearing.blogspot.com/

In the realm of industrial automation, the evolution of precision machinery hinges upon the reliability and efficiency of its components. Among these, RKS.23 0411 slewing ring bearings emerge as indispensable assets, playing a pivotal role in advancing automation technologies.

Slewing ring bearings serve as the backbone of automated systems, facilitating smooth rotation and precise positioning essential for seamless operations. RKS.23 0411, in particular, embodies the pinnacle of engineering excellence, with its cutting edge design and meticulous construction tailored to meet the demanding requirements of modern industries.

These bearings, meticulously crafted from high quality materials and engineered with innovative structural features, exemplify durability and resilience in the face of rigorous industrial environments. The diverse range of sizes available ensures compatibility with a myriad of applications, from robotics to aerospace, further solidifying RKS.23 0411’s status as a cornerstone of industrial automation.

As we delve deeper into the intricacies of RKS.23 0411 slewing ring bearings, it becomes evident that proper installation and maintenance are paramount. Bold Adherence to meticulous installation guidelines and regular lubrication practices not only optimize performance but also extend the operational lifespan of these critical components.

Moreover, proactive maintenance measures, guided by comprehensive wear rate analysis, allow for the timely detection and mitigation of potential issues, thus safeguarding the efficiency and reliability of industrial processes.

In the event of faults or failures, industry leading repair procedures ensure swift resolution, minimizing downtime and maximizing productivity. Additionally, access to technical support from slewing ring bearing manufacturers provides invaluable assistance, underscoring their commitment to customer satisfaction and operational excellence.

In conclusion, RKS.23 0411 slewing ring bearings represent the epitome of precision and reliability in industrial automation. As manufacturers continue to innovate and refine these essential components, they remain steadfast in their commitment to driving progress and efficiency across diverse industrial sectors.

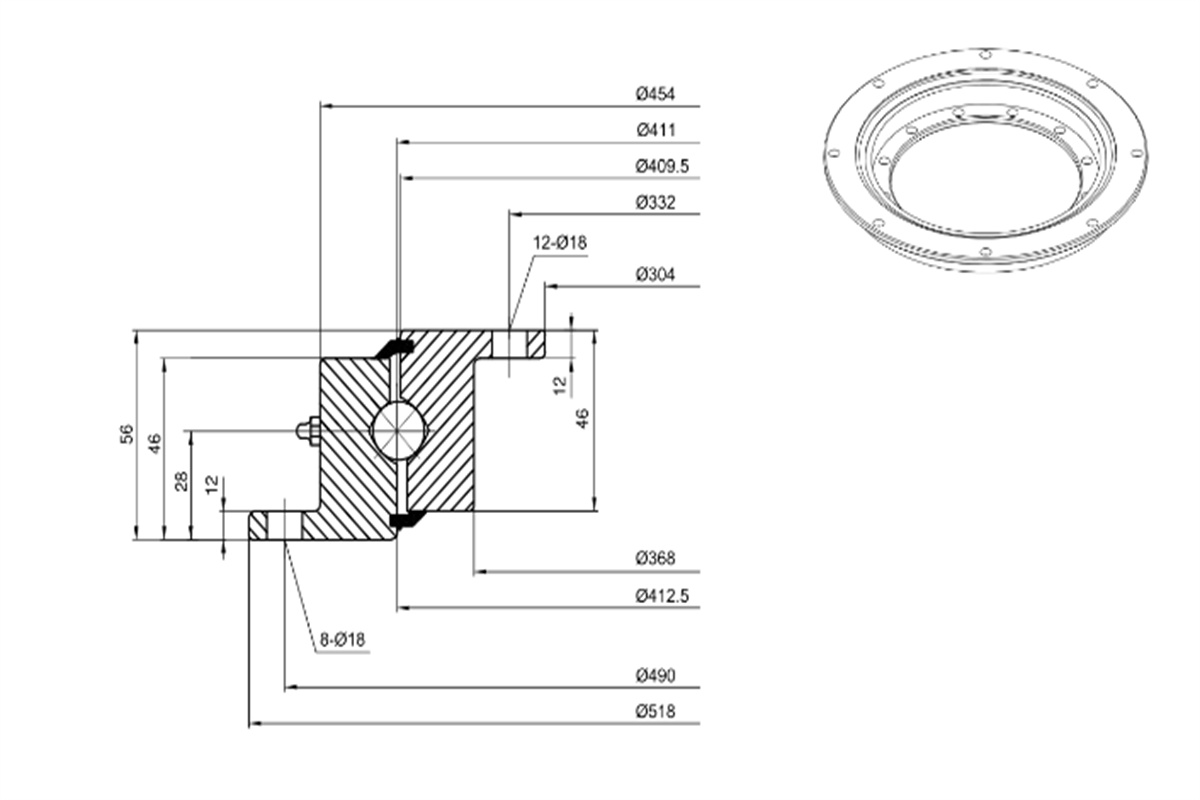

Product Attributes of RKS.21 0411

| Product Attributes of RKS.21 0411 | |

| Specifications | |

| Part Number | RKS.21 0411 |

| Gear | external gear |

| Geometry | |

| weight | 32,0 kg |

| dm | 411 |

| D | 505 |

| D2 | 412,5 |

| d | 304 |

| d1 | 368 |

| d2 | 409,5 |

| Attachment bolt holes | |

| Outer ring | |

| Je | 455 mm |

| Ke | M 12 |

| Ne | 10 |

| inner ring | |

| Ji | 332 mm |

| Ki | 18 |

| Ni | 12 |

| Gear Data | |

| Gear Dimensions(d01) | 495 mm |

| Module(m) | 5 |

| Number of teeth(z) | 99 |

| Permissible tooth forces T(fnormal) | 12 KN |

| Permissible tooth forces T(fMAX) | 46 |

| Basic load ratings | |

| axial dynamic (C) | 169 KN |

| static (C0) | 284 |

| Static limitingload diagram | |

| Raceway curves | r1 |

| Bolt curves | b1 |

Material Specifications, Structural Features, and Size Range

The superiority of RKS.23 0411 slewing ring bearings lies not only in their advanced design but also in the meticulous selection of materials and structural features tailored to meet the demands of industrial automation.

At the heart of RKS.23 0411’s excellence is its construction from premium grade materials known for their exceptional strength, durability, and resistance to wear. These materials undergo rigorous testing and quality control measures to ensure compliance with stringent industry standards, guaranteeing reliability and longevity in operation.

Structurally, RKS.23 0411 bearings are engineered with precision to optimize load distribution and withstand the extreme forces encountered in industrial environments. Their innovative design features bold such as raceway profiles and sealing mechanisms maximize efficiency while minimizing friction and wear.

Moreover, the extensive range of sizes available in the RKS.23 0411 series caters to a wide spectrum of industrial applications, from heavy duty machinery to precision robotics. Whether in compact assemblies or largescale installations, RKS.23 0411 bearings offer unparalleled versatility and adaptability, empowering industries to achieve optimal performance and efficiency.

In summary, the combination of superior material specifications, innovative structural features, and a diverse size range positions RKS.23 0411 slewing ring bearings as the cornerstone of precision and reliability in industrial automation. As industries continue to evolve, these bearings remain steadfast in their commitment to driving progress and innovation across diverse applications.

The RKS.23 0411 Bearing: Specifications and Design Features

| Feature | Description |

| Type | Four point contact ball slewing bearing |

| Size | Specific dimensions specified by internal and external diameters, and width |

| Load Capacity | Axial Load Capacity Radial Load Capacity Moment Load Capacity |

| Materials | Inner and Outer Rings: High strength steel or alloy materials Rolling Elements: Ball bearings |

| Sealing | Optional sealing arrangements to protect against contaminants |

| Mounting Holes | Pre-drilled holes on the outer ring for easy installation |

| Gear Options | Gear teeth may be present on the inner or outer ring for direct meshing with other components |

| Precision | Designed with precision tolerances for smooth operation and accurate positioning |

| Corrosion Protection | Surface treatments or coatings may be applied for enhanced corrosion resistance |

| Operating Temperature | Designed to operate within a specified temperature range |

images source:https://www.lily-bearing.com

Installation Guidelines and Lubrication Practices

Efficient installation and proper lubrication are essential elements in unlocking the full potential of RKS.23 0411 slewing ring bearings, ensuring optimal performance and longevity in industrial automation systems.

Installation begins with meticulous adherence to manufacturer provided guidelines, encompassing bold precise alignment, torque specifications, and preload settings. Each step is crucial in guaranteeing the seamless integration of RKS.23 0411 bearings into the machinery, minimizing stress points and maximizing operational efficiency.

Furthermore, bold the application of appropriate lubricants is paramount in mitigating friction, reducing wear, and maintaining the operational integrity of RKS.23 0411 bearings. Lubrication practices should align with manufacturer recommendations, taking into account factors such as operating temperatures, load conditions, and environmental considerations.

Regular maintenance intervals should include inspections of lubrication levels and conditions, with bold timely replenishment or replacement as necessary to sustain optimal performance. By prioritizing proper installation and lubrication practices, industries can ensure the reliability and longevity of RKS.23 0411 slewing ring bearings, thus maximizing the efficiency and productivity of their automation systems.

Maintenance, Wear Rates, and Service Life Expectancy

Maintenance plays a pivotal role in preserving the performance and extending the service life of RKS.23 0411 slewing ring bearings, ensuring uninterrupted operation and minimizing downtime in industrial automation settings.

Regular maintenance routines, guided by manufacturer recommendations, are essential to monitor wear rates and detect potential issues before they escalate. bold Comprehensive inspections allow for the timely identification of worn components or abnormalities, facilitating proactive interventions to prevent premature failure.

Wear rates of RKS.23 0411 bearings are influenced by various factors, including operating conditions, loads, and environmental factors. Through meticulous analysis and monitoring, industries can gauge the rate of wear and anticipate maintenance needs, thereby optimizing service life expectancy and minimizing unplanned downtime.

Proactive maintenance measures, such as bold lubrication replenishment and component replacement, are instrumental in mitigating wear and preserving the integrity of RKS.23 0411 bearings. By adhering to recommended maintenance schedules and implementing corrective actions promptly, industries can safeguard the reliability and efficiency of their automation systems, ensuring seamless operations and maximizing productivity.

Replacement, Interchangeability, and Model Alternatives

In the dynamic landscape of industrial automation, the ability to seamlessly replace components is crucial to minimizing downtime and optimizing operational efficiency. RKS.23 0411 slewing ring bearings offer versatility and compatibility, facilitating smooth replacement processes and providing flexibility in diverse industrial applications.

Guidelines for replacement of RKS.23 0411 bearings emphasize bold proper disassembly and reassembly procedures, ensuring precision and alignment during the replacement process. Compatibility with other models and alternatives allows for easy interchangeability, enabling industries to adapt to evolving needs and technologies without significant disruptions.

Considerations for interchangeability extend beyond direct replacements, with industries benefiting from the ability to retrofit existing systems with newer models or alternative solutions. bold Compatibility assessments aid in identifying suitable replacements or upgrades, maximizing the efficiency and longevity of automation systems while minimizing associated costs.

By embracing the versatility and interchangeability of RKS.23 0411 slewing ring bearings, industries can navigate the complexities of industrial automation with confidence, seamlessly integrating innovative solutions to drive progress and efficiency.

Fault Diagnosis, Repair Procedures, and Technical Support

Despite the robust design and reliability of RKS.23 0411 slewing ring bearings, occasional faults or failures may occur in industrial automation settings. Prompt diagnosis and effective repair procedures are essential to minimize downtime and restore operations swiftly.

Common failure modes of RKS.23 0411 bearings, such as bold abnormal noise, vibration, or reduced performance, warrant immediate attention and diagnosis. Through bold comprehensive fault analysis, industries can pinpoint the root cause of issues and implement targeted repair solutions.

Repair procedures for RKS.23 0411 bearings are outlined in detail by manufacturers, offering stepbystep guidance for disassembly, inspection, and replacement of faulty components. bold Expertise from qualified technicians ensures precision and quality in repair operations, maximizing the likelihood of a successful restoration of functionality.

Access to technical support from slewing ring bearing manufacturers further enhances fault diagnosis and repair capabilities. bold Knowledgeable assistance and troubleshooting guidance empower industries to overcome challenges and optimize the performance of their automation systems, ensuring continuity and reliability in operations.

Slewing Ring Bearing Manufacturers: Expertise and Support

In the realm of industrial automation, the expertise and support provided by slewing ring bearing manufacturers are instrumental in ensuring the reliability and efficiency of critical components such as RKS.23 0411 bearings.

Leading manufacturers boast extensive experience and technical knowledge in slewing ring bearing design, production, and application. Their commitment to innovation and quality assurance translates into superior products that meet the demanding requirements of modern industries.

Slewing ring bearing manufacturers offer comprehensive support services, including bold technical assistance, product customization, and aftermarket support. Their dedicated teams of engineers and customer service professionals are equipped to address inquiries, provide guidance on product selection and integration, and offer tailored solutions to meet specific application needs.

Moreover, manufacturers’ resources encompass bold training programs, documentation, and online portals designed to empower customers with the knowledge and tools necessary to maximize the performance and longevity of RKS.23 0411 bearings. Access to these resources ensures industries are equipped to overcome challenges, optimize operations, and drive innovation in industrial automation.

By partnering with reputable slewing ring bearing manufacturers, industries gain access to a wealth of expertise and support, enabling them to navigate the complexities of industrial automation with confidence and achieve sustained success.

The method to measure the wear of Rks 23 0411 slewing ring bearings

| Measurement Method | Description |

| Visual Inspection | Visually inspect the bearing for signs of wear such as pitting, spalling, scoring, or discoloration. |

| Dimensional Measurement | Measure critical dimensions such as inner and outer ring diameters, raceway depth, and ball diameter. |

| Axial and Radial Clearance | Check axial and radial clearance using precision instruments like dial indicators or feeler gauges. |

| Vibration Analysis | Conduct vibration analysis to detect abnormal vibration patterns indicating wear or damage. |

| Noise Monitoring | Listen for abnormal noises during operation, such as grinding, rattling, or squeaking. |

| Lubricant Analysis | Analyze lubricant condition for contaminants, oxidation, or depletion of additives. |

| Load Testing | Perform load testing within specified limits and monitor for signs of wear or fatigue. |

| Endoscopic Inspection | Use endoscopic cameras to visually inspect internal components for wear or damage. |

Which bearings can be replaced with RKS.23 0411 bearing 304x518x56mm?

When replacing the RKS.23 0411 bearing with dimensions of 304x518x56mm, it’s crucial to find bearings that have the same or compatible dimensions and load-bearing capabilities. The RKS.23 0411 bearing is a four-point contact ball slewing bearing.This type of bearing is commonly used in various applications requiring rotational movement, such as cranes, excavators, and wind turbines.To determine if the RKS.23 0411 bearing can replace another bearing, you need to consider several factors:

| Consideration | Description |

| Size Compatibility | Those of the bearing you want to replace match the dimension of the RKS.23 0411 bearing ,the RKS.23 0411 bearing has dimensions of 304x518x56mm. |

| Load Capacity | Ensure that the RKS.23 0411 bearing can handle the same or higher loads compared to the bearing you want to replace. Check the load ratings provided by the manufacturer. |

| Mounting Configuration | Verify if the mounting configuration of the RKS.23 0411 bearing matches that of the bearing you want to replace. This includes bolt hole pattern, hole diameter, and other mounting features. |

| Operating Conditions | Consider the operating conditions such as speed, temperature, and environment to ensure that the RKS.23 0411 bearing is suitable for the application. |

| Application Compatibility | Make sure that the RKS.23 0411 bearing is suitable for the specific application in terms of performance and durability. |

images source:https://www.techniekwebshop.nl

FAQs about RKS.23 0411 Slewing Ring Bearings:

1.What is an RKS.23 0411 Slewing Ring Bearing?

An RKS.23 0411 Slewing Ring Bearing is a type of rotating bearing designed to handle axial, radial, and moment loads simultaneously. It consists of inner and outer rings with rolling elements arranged between them to facilitate smooth rotation.

The RKS.23 0411 Slewing Ring Bearing is a specialized bearing designed for demanding applications where smooth rotation, high load capacity, and reliability are crucial. Its design and capabilities make it an integral component in various types of machinery and equipment across multiple industries.

2.What are the primary features of RKS.23 0411 Slewing Ring Bearings?

RKS.23 0411 Slewing Ring Bearings are characterized by their four point contact design, which allows them to accommodate axial, radial, and moment loads with a single bearing. They offer high load capacity, precision rotation, and compact design.

Four-Point Contact Design : The RKS.23 0411 bearing utilizes a four-point contact design, which allows it to accommodate axial, radial, and moment loads simultaneously. This design minimizes stress concentrations and ensures even load distribution, enhancing the bearing’s load-bearing capacity and stability.

High Load Capacity: Despite its compact size, the RKS.23 0411 slewing ring bearing offers high load-bearing capacity, making it suitable for applications requiring the handling of heavy loads. It can withstand significant axial, radial, and moment loads without compromising performance or reliability.

Smooth Rotation: The arrangement of rolling elements between the inner and outer rings facilitates smooth rotation of the bearing, ensuring precise and consistent movement. This feature is crucial for applications where accurate positioning and smooth operation are essential, such as cranes, excavators, and wind turbines.

3.What are the typical applications of RKS.23 0411 Slewing Ring Bearings?

RKS.23 0411 Slewing Ring Bearings are commonly used in various industrial applications, including construction machinery (cranes, excavators), material handling equipment, wind turbines, radar antennas, and more, where smooth rotation and high load capacity are required.

Construction Machinery:

Cranes: Tower cranes, mobile cranes, and crawler cranes rely on slewing ring bearings for smooth rotation of the boom and jib during lifting operations.

Excavators: Slewing bearings facilitate the rotation of the upper structure, allowing for precise control of the digging and loading processes.

Material Handling Equipment:

Conveyor Systems: Slewing ring bearings enable the rotation of conveyor belts and pulleys, facilitating the movement of materials in factories, warehouses, and distribution centers.

Stacker-Reclaimer Machines: Used in bulk material handling operations at ports, mines, and storage facilities, slewing bearings support the rotational movement of the boom and bucket wheel.

Wind Turbines:

Slewing ring bearings support the rotation of the nacelle, which houses the rotor and other components, allowing wind turbines to harness wind energy efficiently for electricity generation.

Radar Antennas:

Radar systems utilize slewing ring bearings to enable the rotation of antennas, enabling precise scanning and tracking of targets in military, aviation, meteorological, and communication applications.

Renewable Energy:

Wind Turbines: Slewing bearings play a crucial role in the yaw and pitch systems of wind turbines, allowing the rotor to adjust its orientation and blade angle for optimal wind capture.

Solar Tracking Systems: Slewing bearings enable solar panels to track the sun’s movement throughout the day, maximizing solar energy capture in photovoltaic and concentrated solar power systems.

Compact Design: The RKS.23 0411 slewing ring bearing is designed with a compact structure, allowing it to be installed in tight spaces without sacrificing performance. Its compact design makes it versatile for various applications where space is limited.

Robust Construction: Constructed from high-quality materials, such as high-strength steel or alloy, the RKS.23 0411 slewing ring bearing offers durability and reliability even in demanding operating conditions. It is engineered to withstand harsh environments, temperature variations, and heavy loads over prolonged periods.

Versatility: RKS.23 0411 slewing ring bearings are suitable for a wide range of industrial applications across different sectors, including construction machinery, material handling equipment, wind turbines, radar antennas, and more. Their versatility makes them indispensable components in various types of machinery and equipment.

3.What are the typical applications of RKS.23 0411 Slewing Ring Bearings?

RKS.23 0411 Slewing Ring Bearings are commonly used in various industrial applications, including construction machinery (cranes, excavators), material handling equipment, wind turbines, radar antennas, and more, where smooth rotation and high load capacity are required.

Construction Machinery:

Cranes: Tower cranes, mobile cranes, and crawler cranes rely on slewing ring bearings for smooth rotation of the boom and jib during lifting operations.

Excavators: Slewing bearings facilitate the rotation of the upper structure, allowing for precise control of the digging and loading processes.

Material Handling Equipment:

Conveyor Systems: Slewing ring bearings enable the rotation of conveyor belts and pulleys, facilitating the movement of materials in factories, warehouses, and distribution centers.

Stacker-Reclaimer Machines: Used in bulk material handling operations at ports, mines, and storage facilities, slewing bearings support the rotational movement of the boom and bucket wheel.

Wind Turbines:

Slewing ring bearings support the rotation of the nacelle, which houses the rotor and other components, allowing wind turbines to harness wind energy efficiently for electricity generation.

Radar Antennas:

Radar systems utilize slewing ring bearings to enable the rotation of antennas, enabling precise scanning and tracking of targets in military, aviation, meteorological, and communication applications.

Renewable Energy:

Wind Turbines: Slewing bearings play a crucial role in the yaw and pitch systems of wind turbines, allowing the rotor to adjust its orientation and blade angle for optimal wind capture.

Solar Tracking Systems: Slewing bearings enable solar panels to track the sun’s movement throughout the day, maximizing solar energy capture in photovoltaic and concentrated solar power systems.

4.What are the load capacities of RKS.23 0411 Slewing Ring Bearings?

The load capacities of RKS.23 0411 Slewing Ring Bearings depend on factors such as size, design, and operating conditions. Manufacturers provide load capacity charts and specifications for different models under various load scenarios.

Axial Load Capacity:The axial load capacity refers to the maximum load that the bearing can withstand in the axial direction, parallel to the axis of rotation. This includes loads applied along the vertical or horizontal axis of the bearing.

Axial load capacity is crucial in applications where vertical or horizontal forces are predominant, such as cranes and excavators.

Radial Load Capacity:The radial load capacity indicates the maximum load that the bearing can support in the radial direction, perpendicular to the axis of rotation. This includes loads applied from the side or perpendicular to the rotational axis.

Radial load capacity is essential for applications where side loads or off-center forces are present, such as conveyor systems and wind turbines.

Moment Load Capacity:The moment load capacity refers to the maximum torque or bending moment that the bearing can withstand without excessive deflection or deformation. This includes twisting or bending forces applied perpendicular to the radial or axial direction.Moment load capacity is critical in applications where torque or bending forces are significant, such as robotic arms and indexing tables.

5.How should RKS.23 0411 Slewing Ring Bearings be installed and maintained?

Proper installation of RKS.23 0411 Slewing Ring Bearings involves precise alignment and mounting according to manufacturer guidelines. Regular maintenance, including lubrication, inspection for wear or damage, and timely replacement of worn components, is essential to ensure optimal performance and longevity.

Installation:

Alignment: Ensure precise alignment of the bearing with the surrounding components and mounting structure. Misalignment can lead to premature wear and reduced bearing life.

Mounting: Follow the manufacturer’s guidelines for mounting the bearing securely to the support structure or machinery. Use appropriate fasteners and torque settings to ensure proper installation.

Preparation: Clean all mating surfaces thoroughly to remove dirt, debris, and contaminants that could affect bearing performance.

Inspection: Check the bearing and mounting surfaces for any signs of damage or defects before installation. Address any issues promptly to prevent further damage during operation.

Maintenance:

Lubrication: Regularly lubricate the bearing according to the manufacturer’s recommendations. Use the appropriate type and amount of lubricant to ensure smooth operation and prevent premature wear.

Inspection: Periodically inspect the bearing for signs of wear, damage, or abnormal noise during operation. Pay attention to any changes in performance or operating conditions that may indicate potential issues.

Cleaning: Keep the bearing and surrounding components clean to prevent the buildup of dirt, debris, and contaminants that could impair performance or cause premature failure.

Replacement: Replace worn or damaged components, such as seals, rolling elements, or raceways, as needed. Timely replacement of worn parts helps maintain the integrity and reliability of the bearing.

Alignment Check: Regularly check and adjust the alignment of the bearing if necessary to ensure optimal performance and longevity.

Environmental Considerations: Consider environmental factors such as temperature, humidity, and exposure to corrosive substances when planning maintenance activities. Take appropriate measures to protect the bearing from adverse conditions.

6.What are the advantages of using RKS.23 0411 Slewing Ring Bearings?

RKS.23 0411 Slewing Ring Bearings offer several advantages, including high load capacity, compact design, smooth rotation, and the ability to handle axial, radial, and moment loads simultaneously. They provide reliability and precision in various industrial applications.

All-round load capacity

The best part of using PSR bearings in any system is that they provide 360 degrees of joint support even when used for complex load-bearing systems. The bearings allow for a concurrent movement on multiple axes.

Shaftless bearings

When these bearings get made, you will observe that they happen to be without a shaft/ spindle, which works as an advantage. The bearing is now an enhancement in the bearing motion and gives more space to the system’s other components.

Increase in load capacity

You will find an automatic increase in the bearings’ load-carrying capacity because of the design change. They are now capable of handling heavy loads during movement efficiently.

The right amount of stiffness

Precision slewing ring bearings can facilitate a wide range of motions because of the high material stiffness. It is the ideal amount that is ample enough to provide support for the rigid ball bearing applications

Lesser friction

Since the components are fewer because there aren’t any shafts or spindles, you will find lesser friction that these ball bearings will impose on the movement even with heavy loads. The freedom of movement is another aspect that gives the upper hand in providing optimum efficiency. The life of the bearings gets comparatively increased because of the above factors and surrounding components.

More service life

The durability of such bearings increases due to the reduction in friction. The load-bearing capacity is adjusted to ensure that it reduces the stress on the bearings and the adjacent components. With the number of components decreasing, you will find that the system will last longer and have lesser maintenance issues.

7.Where can I purchase RKS.23 0411 Slewing Ring Bearings?

RKS.23 0411 Slewing Ring Bearings can be purchased from authorized distributors or directly from manufacturers. It’s essential to source bearings from reputable suppliers to ensure quality and reliability.

Authorized Distributors:

Many manufacturers of slewing ring bearings have authorized distributors who sell their products. These distributors often have extensive networks and can provide technical support and assistance with product selection.

Directly from Manufacturers:

Some manufacturers of slewing ring bearings sell their products directly to customers. This option may be suitable for larger orders or for customers who prefer to deal directly with the manufacturer.

Online Marketplaces:

Online marketplaces such as Alibaba, Amazon, and eBay may have listings for RKS.23 0411 Slewing Ring Bearings from various sellers. Be sure to check the seller’s reputation and reviews before making a purchase.

Industrial Suppliers:

Industrial suppliers and wholesalers that specialize in bearings and power transmission components may carry RKS.23 0411 Slewing Ring Bearings or be able to source them for you.

Trade Shows and Exhibitions:

Trade shows and exhibitions related to industrial machinery and equipment often feature exhibitors who specialize in bearings and related products. These events can be a great opportunity to connect with suppliers and learn more about available products.

8.Are there any warranty options available for RKS.23 0411 Slewing Ring Bearing?

Warranty coverage for RKS.23 0411 Slewing Ring Bearings may vary depending on the manufacturer and terms of sale. Check with the supplier or manufacturer for warranty details and any applicable terms and conditions.

Manufacturer’s Warranty:

Many manufacturers offer warranties on their slewing ring bearings to guarantee product quality and performance. The duration and terms of the warranty can vary between manufacturers.

Warranty coverage typically includes defects in materials and workmanship under normal use and operating conditions.

Supplier’s Warranty:

Some suppliers or distributors may offer additional warranty coverage or extended warranties on RKS.23 0411 Slewing Ring Bearings as part of their sales terms.

Be sure to inquire about warranty options when purchasing from a supplier and review the terms and conditions carefully.

Warranty Coverage:

Warranty coverage may include repair, replacement, or refund of the product in the event of a covered defect or failure within the warranty period.

It’s essential to understand the scope of warranty coverage, including any exclusions or limitations, to ensure that your purchase is protected.

Extended Warranty Options:

Some manufacturers or suppliers may offer extended warranty options for an additional fee, providing longer coverage beyond the standard warranty period.

Consider whether extended warranty coverage is beneficial based on the expected lifespan and usage of the slewing ring bearing in your application.

Claim Procedures:

Familiarize yourself with the warranty claim procedures outlined by the manufacturer or supplier. This includes requirements for submitting claims, documentation needed, and procedures for returning or exchanging defective products.

The future of bearings like the RKS.23 0411

The future of bearings like the RKS.23 0411 slewing ring bearing holds promise for advancements in several key areas, driven by emerging technologies and evolving industrial needs. Here are some potential future directions for the RKS.23 0411 and similar bearings:

1.Material Innovations: Future bearings may incorporate advanced materials with superior strength, durability, and wear resistance. Research into novel alloys, ceramics, and nanomaterials could lead to bearings capable of withstanding higher loads, operating in extreme environments, and exhibiting longer service life.

2.Smart Bearing Technology: Integration of sensors, wireless communication, and data analytics into bearings could enable real-time monitoring of performance metrics such as temperature, vibration, and load. Smart bearings could provide valuable insights for predictive maintenance, optimizing equipment uptime, and reducing maintenance costs.

3.Precision Engineering: Continued advancements in manufacturing techniques, such as precision machining and 3D printing, may enable the production of bearings with tighter tolerances and more complex geometries. This could result in bearings that offer improved accuracy, smoother operation, and enhanced reliability.

4.Energy Efficiency: Bearings designed for enhanced energy efficiency could play a crucial role in reducing power consumption and minimizing environmental impact. Features such as low-friction coatings, optimized lubrication systems, and aerodynamic designs may contribute to energy savings in various applications, including wind turbines, industrial machinery, and automotive systems.

5.Customization and Modular Design: The ability to tailor bearings to specific application requirements through customizable design options and modular components could become more prevalent. This flexibility would allow for optimized performance, simplified maintenance, and easier integration into diverse systems.

6.Robotic and Autonomous Systems: Bearings will continue to be essential components in robotic and autonomous systems across industries such as manufacturing, logistics, and healthcare. Future bearings may be designed to meet the unique demands of robotics, including high-speed operation, precise positioning, and resistance to shock and vibration.

7.Environmental Sustainability: Bearings manufactured using sustainable materials and eco-friendly processes could become increasingly important in addressing environmental concerns. Efforts to minimize resource consumption, reduce waste generation, and optimize recycling of bearing components may align with broader sustainability initiatives.

8.Global Collaboration and Standards: Collaboration among industry stakeholders, including manufacturers, researchers, and regulatory bodies, will be essential for establishing global standards and best practices for bearing design, production, and performance evaluation. Harmonized standards could facilitate interoperability, promote innovation, and ensure product quality and reliability.

9.Integration with Emerging Technologies: Bearings may integrate with emerging technologies such as artificial intelligence, virtual reality, and Internet of Things (IoT) platforms to enable new functionalities and applications. For example, AI-driven predictive maintenance algorithms could optimize bearing performance and extend service life based on real-time data analytics.

10.Biomedical and Healthcare Applications: Bearings may find new applications in biomedical devices and healthcare equipment, where precision, reliability, and biocompatibility are critical. Bearings designed for medical robotics, prosthetics, and diagnostic imaging systems could support advancements in patient care and medical technology.

Overall, the future of bearings like the RKS.23 0411 is characterized by continuous innovation, driven by technological advancements and evolving market demands. By embracing these opportunities, bearing manufacturers can contribute to the efficiency, reliability, and sustainability of industrial systems across various sectors.

Reference sources

1.Liebherr-Verzahntechnik GmbH. “Slewing Bearing Technology Handbook.”

2.Fotopoulos, S., Exadaktylos, P., & Theodossiades, S. (2013). Design and analysis of slewing bearings for wind turbines. Renewable Energy.

3.Zheng, W., Dai, J. S., & Xie, G. (2016). Slewing bearing dynamic modelling considering geometric nonlinearity. Mechanism and Machine Theory.

4.Liu, X. J., Zhang, T. T., Cui, Z. H., & Zhang, H. Z. (2020). Finite element analysis and optimal design of a light slewing bearing used in a space manipulator. Mechanism and Machine Theory.

5.Qin, Y., Wang, M., Jin, Y., & Xu, M. (2020). Performance simulation and optimization of slewing bearing used in heavy-duty excavator based on finite element analysis. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science.