Introduction

Slewing ring bearings, also known as turntable bearings or slewing bearings, are critical components used in machinery and equipment to facilitate rotational movement. The manufacturing process of slewing ring bearings involves several intricate steps and advanced technologies to ensure precision, durability, and reliability. Slewing ring bearing manufacturers are vital contributors to numerous industries, facilitating rotational movement in heavy machinery, renewable energy systems, and more. Understanding their significance is essential for ensuring the efficiency and reliability of various applications. This analysis aims to identify and evaluate the top 15 slewing ring bearing manufacturers, shedding light on their pivotal role in modern industries.

Methodology

The selection of the top 15 slewing ring bearing manufacturers was based on a meticulous evaluation process. Criteria such as product quality, manufacturing processes, market reputation, and customer satisfaction were meticulously examined. A comprehensive research approach was employed, including the scrutiny of industry reports, analysis of company websites, review of customer feedback, and consultation with industry experts. This method ensured the inclusion of manufacturers that excel in producing high-quality slewing ring bearings, meeting the diverse needs of various sectors.

Top 15 Slewing Ring Bearing Manufacturers company Background and History: Each of the top 15 manufacturers boasts a distinguished background and extensive experience in the slewing ring bearing industry. Their rich histories reflect a legacy of innovation, reliability, and commitment to excellence.

Here are the top 15 slewing ring bearing manufacturers worldwide, along with brief introductions:

1 RBC Bearings Incorporated( RBC USA)

RBC Bearings Incorporated( RBC USA) is an American manufacturer of slewing ring bearing manufacturers, offering various types of high-performance bearing products, including bearings for turntable equipment.

Unique Capabilities

Wide Product Line:RBC Bearings Incorporated( RBC USA) offers a broad range of products, including spherical bearings, tapered roller bearings, plain bearings, ball screws, and customized bearing solutions.

Customization Capability:The company possesses robust customization capabilities to design and manufacture bespoke bearings tailored to specific customer requirements, catering to diverse application needs.

Technological Advancements

Research and Development Investment:RBC Bearings Incorporated( RBC USA) invests significantly in research and development, collaborating with leading industry technology partners to drive innovation and progress in bearing technology.

Materials Science:The company as one of slewing ring bearing manufacturers focuses on continuously improving bearing materials, employing advanced materials science techniques to enhance bearing performance, wear resistance, and corrosion resistance.

2 Xuzhou Wanda Slewing Bearing Co. Ltd(Wanda China)

xuzhou wanda slewing bearing co.ltd is a comprehensive machinery manufacturer of slewing ring bearing manufacturers in China, with its own brand offering various types of bearing products, including bearings for turntable equipment.

Wanda Slewing Bearing (China) Co., Ltd., commonly known as Wanda, is a prominent manufacturer of slewing bearings in China. Here are its unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Extensive Product Range:Wanda offers a comprehensive range of slewing bearings, including single-row ball, double-row ball, single-row cross roller, and three-row roller slewing bearings. They cater to various industrial applications, including construction machinery, mining equipment, and renewable energy systems.

Customization Expertise: With strong engineering capabilities, Wanda can provide customized slewing bearing solutions tailored to specific customer requirements. They collaborate closely with clients to design and manufacture slewing bearings that meet precise specifications, ensuring optimal performance in diverse applications.

Technological Advancements

Research and Development:Wanda invests significantly in research and development to advance slewing bearing technology. They focus on enhancing bearing materials, manufacturing processes, and design innovations to improve performance, durability, and efficiency.

Quality Assurance:The company implements stringent quality control measures throughout the production process, utilizing advanced testing and inspection techniques to ensure the reliability and accuracy of their slewing bearings.

AST® Bearings LLC (AST USA) is an American bearing manufacturer,which is one of slewing ring bearing manufacturers, specializing in providing customized bearing solutions, including bearings for turntable equipment.

AST® Bearings LLC (AST USA), headquartered in the USA, is a renowned manufacturer from many slewing ring bearing manufacturers and distributor of high-quality bearings. Here are its unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Comprehensive Product Portfolio:AST® Bearings LLC (AST USA) offers a diverse range of bearings, including ball bearings, roller bearings, spherical bearings, and plain bearings. They serve various industries such as aerospace, automotive, industrial machinery, and medical equipment.

Customization Services: With advanced engineering capabilities, AST® Bearings LLC (AST USA) provides custom bearing solutions tailored to meet specific application requirements. They work closely with customers to design and manufacture bearings with unique specifications, dimensions, and materials.

Technological Advancements

Innovative Bearing Designs: AST® Bearings LLC (AST USA) continuously invests in research and development to introduce innovative bearing designs and technologies. They focus on improving bearing performance, reliability, and longevity through advancements in materials, lubrication, and manufacturing processes.

Digital Solutions: The company embraces digital technologies to enhance customer experience and streamline operations. They offer online tools and resources for bearing selection, application analysis, and technical support, making it easier for customers to find the right bearings for their needs.

SKF Group (SKF Sweden) is a leading global supplier of bearings and sealing solutions, offering various types of slewing ring bearings known for their high quality, performance, and reliability.

SKF Group (SKF Sweden) is a leading global supplier of slewing ring bearing manufacturers, seals, lubrication systems, and related services. Here are SKF’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Broad Product Portfolio: SKF Group (SKF Sweden) offers a comprehensive range of products, including ball bearings, roller bearings, plain bearings, and specialized bearing units. They also provide seals, lubrication systems, and condition monitoring equipment.

Global Presence:With a presence in over 130 countries, SKF Group (SKF Sweden) has an extensive network of manufacturing facilities, distribution centers, and service centers worldwide. This global footprint enables them to serve customers efficiently across various industries and regions.

Technological Advancements

Research and Development:SKF Group (SKF Sweden) invests heavily in research and development to drive technological advancements in bearing design, materials, and manufacturing processes. They focus on improving bearing performance, reliability, and energy efficiency.

Digitalization and Connectivity:SKF Group (SKF Sweden)embraces digitalization and connectivity to enhance product performance and enable predictive maintenance solutions. They offer advanced condition monitoring systems, remote monitoring services, and cloud-based platforms to optimize asset management and minimize downtime.

Grease and Lubrication Solutions: SKF Group (SKF Sweden) develops high-performance lubrication solutions designed to extend bearing life and reduce maintenance costs. They offer a wide range of specialty greases, lubricants, and automatic lubrication systems tailored to specific applications and operating conditions.

5 The Schaeffler Group (FAG Germany)

The Schaeffler Group is a global automotive and industrial supplier, providing various types of bearing products, including slewing ring bearings for rotating equipment.

The Schaeffler Group is a renowned global technology company that specializes in manufacturing precision components and systems for automotive and industrial applications. Here are its unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities:

Diverse Product Portfolio:Schaeffler offers a wide range of products, including rolling bearings, plain bearings, linear guidance systems, engine components, and mechatronic systems. They serve various industries such as automotive, aerospace, renewable energy, and industrial machinery.

Customer Collaboration:Schaeffler collaborates closely with slewing ring bearing manufacturers’s customers throughout the product development process, from concept to implementation. Their engineering expertise and application knowledge enable them to provide customized solutions that address unique challenges and improve overall system performance.

Technological Advancements

Innovative Bearing Technologies:Schaeffler is known for its innovative bearing technologies, including ceramic hybrid bearings, X-life bearings with optimized internal geometry, and intelligent bearing systems with integrated sensors for condition monitoring and predictive maintenance.

Future Mobility Solutions:Schaeffler is at the forefront of developing technologies for future mobility, including electric mobility, autonomous driving, and connected vehicles. They offer solutions such as electric drive systems, mechatronic chassis components, and energy management systems to support the transition towards sustainable transportation.

NSK Ltd (NSK Japan) is one of the world’s leading bearing manufacturers, with its products widely used in various industrial and mechanical equipment, including slewing ring bearings.

NSK Ltd (NSK Japan) is a leading global manufacturer of bearings from slewing ring bearing manufacturers, automotive products, precision machinery, and mechatronic products. Here are NSK’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Extensive Product Range: NSK Ltd (NSK Japan) offers a comprehensive range of bearings, including ball bearings, roller bearings, and specialized bearings for various applications such as automotive, industrial machinery, and aerospace.

Integrated Solutions:The company provides integrated solutions that combine bearings with seals, lubrication systems, and condition monitoring technologies to optimize performance, reliability, and maintenance intervals.

Global Presence: With a presence in over 30 countries and regions, NSK has established a strong global network of manufacturing facilities, research and development centers, and sales offices to serve customers worldwide.

Technological Advancements

High-Performance Bearings:NSK Ltd (NSK Japan) is known for its high-performance bearings featuring advanced materials, surface treatments, and internal geometries. These bearings offer superior durability, load capacity, and operating efficiency in demanding applications.

Digital Solutions:NSK Ltd (NSK Japan) embraces digitalization and connectivity to offer advanced condition monitoring systems, predictive maintenance solutions, and remote monitoring services. These digital solutions help customers optimize equipment performance, minimize downtime, and reduce maintenance costs.

NTN Corporation (NTN Japan) is a well-known Japanese bearing manufacturer compared with other slewing ring bearing manufacturers, offering high-quality bearing products, including bearings for turntable equipment.

NTN Corporation (NTN Japan), a leading global manufacturer of bearings, constant velocity joints, and precision equipment components, possesses unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Comprehensive Product Portfolio:NTN Corporation (NTN Japan) offers a wide range of products, including ball bearings, roller bearings, automotive bearings, precision machinery, and components for various industrial applications. Their product portfolio caters to diverse industries such as automotive, aerospace, construction, and industrial machinery.

Engineering Expertise: NTN Corporation (NTN Japan) has a strong team of engineers and researchers compared with other slewing ring bearing manufacturers dedicated to product development and innovation. They leverage their expertise to design and manufacture customized solutions tailored to meet specific customer requirements, addressing various challenges in industrial engineering.

Global Presence: With a global network of manufacturing facilities, research centers, and sales offices, NTN has a strong presence in key markets worldwide. This global footprint enables them to provide localized support and services to customers across different regions.

Technological Advancements

Advanced Bearing Technologies:NTN Corporation (NTN Japan) is known for its advancements in bearing technologies, including high-performance materials, innovative designs, and advanced lubrication systems compared with other slewing ring bearing manufacturers. They continuously invest in research and development to improve bearing performance, reliability, and lifespan, meeting the evolving demands of industrial applications.

Sustainable Solutions:NTN Corporation (NTN Japan) is committed to sustainability and environmental responsibility. They develop eco-friendly products, implement energy-efficient manufacturing processes, and support initiatives to reduce carbon emissions and resource consumption in industrial operations.

Timken Company is a renowned American bearing manufacturer, with its products covering multiple sectors such as automotive, aerospace, and industrial equipment, including slewing ring bearings.

The Timken Company, headquartered in the USA, is a global leader in engineered bearings and power transmission products. Here are Timken’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Broad Product Portfolio:Timken offers a wide range of bearings, including tapered roller bearings, cylindrical roller bearings, spherical roller bearings, and ball bearings, along with related components such as seals, lubricants, and housings.

Integrated Solutions:The company provides integrated solutions that combine bearings with other components and systems to meet specific customer needs compared with other slewing ring bearing manufacturers. These solutions often include advanced sealing technologies, lubrication systems, and condition monitoring equipment.

Customization Expertise:Timken has extensive customization capabilities, allowing them to design and manufacture bearings tailored to meet unique application requirements. They work closely with customers to develop custom solutions that optimize performance, reliability, and efficiency.

Technological Advancements

Advanced Engineering:Timken invests heavily in research and development to advance bearing design, materials, and manufacturing processes. They continuously innovate to improve bearing performance, durability, and energy efficiency, using state-of-the-art engineering tools and simulation technologies.

Digital Solutions:The company embraces digitalization to enhance product development, manufacturing processes, and customer service. They offer digital tools and platforms for bearing selection, application analysis, and predictive maintenance, helping customers optimize equipment performance and reduce total cost of ownership.

9 NACHI-FUJIKOSHI CORP (NACHI-Fujikoshi Japan)

NACHI-Fujikoshi is a well-known Japanese bearing manufacturer compared with other slewing ring bearing manufacturers, renowned for its high-performance and reliable products, including bearings for turntable equipment.

NACHI-Fujikoshi Corp., based in Japan, is a global manufacturer of cutting-edge industrial machinery and precision components. Here are NACHI-Fujikoshi’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Wide Product Range:NACHI-Fujikoshi offers a diverse array of products, including bearings, hydraulic equipment, robots, cutting tools, and machine tools. Their comprehensive product portfolio caters to various industries such as automotive, aerospace, electronics, and industrial machinery.

Integrated Solutions:The company provides integrated solutions that encompass multiple technologies and components to address complex engineering challenges. They offer complete systems and assemblies, combining bearings, actuators, controllers, and other components for seamless integration into customer applications.

Technological Advancements

Innovative Engineering:NACHI-Fujikoshi is slewing ring bearing manufacturers at the forefront of engineering innovation, continuously developing advanced technologies and solutions to enhance industrial performance. They invest in research and development to improve product design, materials, and manufacturing processes, driving efficiency and competitiveness.

Robotics and Automation:The company specializes in robotics and automation solutions for industrial applications. They offer a wide range of robots, including articulated robots, SCARA robots, and Cartesian robots, equipped with advanced control systems and vision technology for precise and flexible automation.

THK Co., Ltd.(THK Japan) is a Japanese manufacturer of linear motion systems,which is more famous than slewing ring bearing manufacturers , offering various types of bearing products, including bearings for turntable equipment.

THK Co., Ltd., based in Japan, is a global leader in the development and manufacturing of motion control systems, including linear motion guides, ball screws, actuators, and related components. Here are THK’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Specialization in Linear Motion:THK Co., Ltd.(THK Japan) specializes in linear motion technologies, offering a comprehensive range of linear motion guides, ball screws, linear actuators, and related components. They provide precision solutions for various industries, including automotive, aerospace, semiconductor manufacturing, and medical equipment.

Customization Expertise:THK Co., Ltd.(THK Japan) has extensive customization capabilities, allowing them to design and manufacture bespoke solutions tailored to meet specific customer requirements. They collaborate closely with customers to develop custom motion control systems that optimize performance, minimize footprint, and enhance overall productivity.

Technological Advancements

Advanced Linear Motion Technologies:THK Co., Ltd.(THK Japan) and other slewing ring bearing manufacturers invest heavily in research and development to advance linear motion technologies. They continuously innovate in areas such as bearing design, lubrication systems, and precision machining techniques to improve product performance, reliability, and lifespan.

Digitalization and Smart Solutions:THK Co., Ltd.(THK Japan) embraces digitalization and smart technologies to enhance product functionality and customer experience. They offer digital tools and connectivity solutions for remote monitoring, predictive maintenance, and optimization of motion control systems, enabling improved productivity and uptime for customers.

11 NTN SNR EUROPE (NTN-SNR France)

NTN SNR EUROPE (NTN-SNR France) is a French bearing manufacturer, with its products covering various sectors such as automotive and industrial equipment, providing slewing ring bearingproducts with other slewing ring bearing manufacturers.

NTN SNR EUROPE (NTN-SNR France), headquartered in France, is a leading manufacturer of bearings, bearing units, and associated products for various industrial applications. Here are NTN-SNR’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Extensive Product Range:NTN-SNR offers a comprehensive range of bearings, bearing units, and related products, including ball bearings, roller bearings, automotive bearings, and precision bearings. They also provide bearing housings, seals, and lubrication systems to complement their bearing solutions.

Engineering Expertise:NTN-SNR has a team of skilled engineers and technical experts dedicated to product development and innovation. They collaborate closely with customers to understand their requirements and provide customized solutions that address unique challenges in industrial applications.

Technological Advancements

Advanced Bearing Technologies:NTN-SNR is known for its advancements in bearing design, materials, and manufacturing processes. They and other slewing ring bearing manufacturers continuously invest in research and development to improve bearing performance, reliability, and durability, using state-of-the-art engineering tools and simulation technologies.

Digitalization and IoT Solutions:The company embraces digitalization and the Internet of Things (IoT) to enhance product functionality and customer experience. They offer digital solutions and connectivity platforms for condition monitoring, predictive maintenance, and remote diagnostics, enabling customers to optimize equipment performance and minimize downtime.

In summary, NTN-SNR stands out with its extensive product range, engineering expertise, technological innovations, and commitment to sustainability. Through continuous investment in research and development and collaboration with customers, NTN-SNR contributes to driving progress and excellence in industrial engineering, supporting the success of industries worldwide.

12 Kaydon Bearings (Kaydon USA)

Kaydon Bearings (Kaydon USA) is an American bearing manufacturer, focusing on providing high-performance bearing products, including bearings for turntable equipment.

Unique Capabilities

Specialization in Thin Section Bearings:Kaydon Bearings (Kaydon USA)specializes in the design and manufacture of thin section bearings, which are characterized by their compact, lightweight design and ability to operate in tight spaces compared with other slewing ring bearing manufacturers. These bearings are ideal for applications where space and weight are critical factors, such as aerospace, robotics, and medical equipment.

Expertise in Slewing Ring Bearings:The company also offers a wide range of slewing ring bearings with different slewing ring bearing manufacturers, which provide rotational support for heavy machinery and equipment. Kaydon’s slewing ring bearings are known for their high load capacity, precision, and reliability, making them suitable for applications such as cranes, excavators, and wind turbines.

Technological Advancements:

Advanced Bearing Design:Kaydon Bearings (Kaydon USA) invests in research and development to advance bearing design and manufacturing techniques. They continuously innovate to improve bearing performance, reliability, and longevity, using advanced materials, coatings, and manufacturing processes.

Digital Solutions: The company leverages digital technologies to enhance product development, manufacturing processes, and customer service. They offer digital tools and platforms for bearing selection, application analysis, and predictive maintenance, enabling customers to optimize equipment performance and reduce downtime.

Simulation and Testing: Kaydon Bearings (Kaydon USA) utilizes simulation and testing technologies to validate and optimize bearing designs. They conduct rigorous testing to ensure that their bearings meet or exceed industry standards for performance, durability, and reliability.

13 CW Bearing Co., Ltd (CW China)

CW Bearing Co., Ltd is a Chinese bearing manufacturer, offering reliable quality products with competitive prices, including various bearing products such as slewing ring bearings.

CW Bearing Co., Ltd., based in China, is a prominent manufacturer of high-quality bearings for various industrial applications. Here are CW Bearing’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Advanced Manufacturing Facilities:CW Bearing operates state-of-the-art manufacturing facilities equipped with advanced machinery and technology. This allows them to produce a wide range of bearings, including ball bearings, roller bearings, and specialty bearings, with high precision and consistency.

Broad Product Portfolio:The company offers a comprehensive portfolio of bearings to cater to diverse industries such as automotive, aerospace, agriculture, and industrial machinery. Their product range includes standard bearings, custom-designed bearings, and specialized bearings for specific applications.

Technological Advancements

Continuous Research and Development: CW Bearing Co., Ltd invests in research and development to advance bearing technology and manufacturing process. They focus on improving bearing performance, durability, and reliability through innovations in materials, lubrication, and sealing technologies.

Quality Assurance:The company adheres to stringent quality control standards throughout the manufacturing process, from raw material procurement to final product inspection. They employ advanced testing equipment and quality assurance procedures to ensure that their bearings meet or exceed industry standards.

Digitalization and Smart Manufacturing:CW Bearing Co., Ltd embraces digitalization and smart manufacturing technologies to enhance productivity, efficiency, and quality. They utilize automation, data analytics, and connectivity solutions to optimize production processes, reduce lead times, and minimize defects.

SNR Company (SNR France) is a French bearing manufacturer, with its products widely used in sectors like automotive and mechanical equipment, including bearings for turntable equipment.

SNR Company (SNR France), a subsidiary of NTN Corporation, is a renowned manufacturer of bearings and automotive parts, specializing in high-quality products for various industrial applications. Here are SNR’s unique capabilities, technological advancements, and contributions to industrial engineering:

Unique Capabilities

Extensive Product Range:SNR offers a comprehensive range of bearings, bearing units, and automotive parts, including ball bearings, roller bearings, tapered roller bearings, and wheel hub units. Their diverse product portfolio caters to a wide range of industries, including automotive, aerospace, agriculture, and industrial machinery.

Global Presence: SNR has a strong global presence with manufacturing facilities, distribution centers, and sales offices strategically located around the world. This extensive network enables them to serve customers efficiently and provide localized support and services.

Technological Advancements

Advanced Bearing Technologies:SNR Company (SNR France) invests in research and development to advance bearing design, materials, and manufacturing processes. They continuously innovate to improve bearing performance, reliability, and longevity, using state-of-the-art engineering tools and simulation technologies.

Sustainable Manufacturing Practices:SNR Company (SNR France) is committed to sustainability and environmental responsibility. They implement eco-friendly manufacturing processes, develop energy-efficient products, and support initiatives to reduce carbon emissions and waste in industrial operations.

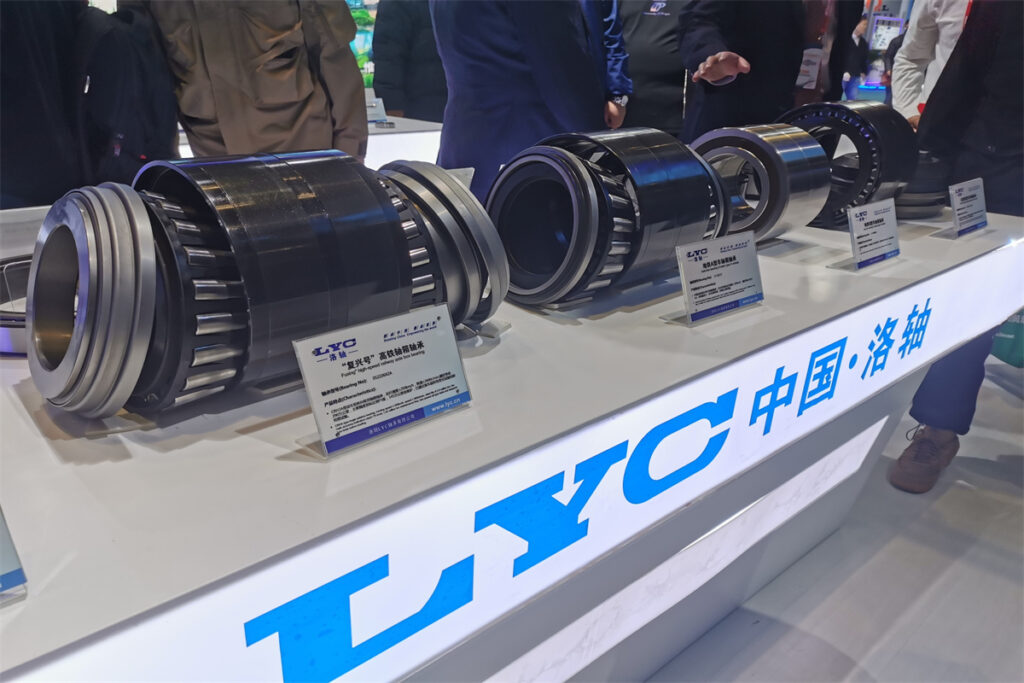

15 LYC Bearing Corporation (LYC China)

LYC Bearing Corporation (LYC China) is one of the well-known bearing manufacturers in China, providing various types of high-quality bearing products, including slewing ring bearings.

Unique Capabilities

Vertical Integration:LYC Bearing Corporation (LYC China) has achieved vertical integration across the entire production process, from raw material sourcing to final product manufacturing. This allows them to maintain strict quality control standards and ensure the consistency and reliability of their bearings.

Diverse Product Portfolio: The company offers a comprehensive range of bearings, including deep groove ball bearings, cylindrical roller bearings, spherical roller bearings, and tapered roller bearings. They also provide custom-designed bearings to meet specific customer requirements.

Customization Expertise:LYC Bearing Corporation (LYC China)specializes in providing customized solutions tailored to meet the unique needs of customers across various industries. Their engineering team works closely with customers to develop bespoke bearing solutions that optimize performance, reliability, and efficiency.

Technological Advancements

Advanced Manufacturing Techniques: LYC Bearing Corporation (LYC China)employs advanced manufacturing techniques and precision machinery to produce bearings with tight tolerances and high performance. They continuously invest in research and development to improve manufacturing processes and introduce innovative technologies.

Digitalization and Automation:LYC Bearing embraces digitalization and automation to enhance productivity, efficiency, and quality in manufacturing processes. They leverage automation technologies for precision machining, assembly, and quality control to ensure consistent product quality and reliability.

Comparative Analysis

The comparative analysis of the top 15 slewing ring bearing manufacturers offers valuable insights into their respective strengths and weaknesses:

Product Quality: Each manufacturer’s commitment to product quality is a defining factor in their reputation and market standing. While some excel in precision engineering and durability, others may prioritize innovation and customization.

Innovation: Innovation drives competitiveness in the slewing ring bearing industry, with manufacturers continually striving to enhance performance and efficiency. Companies that invest in research and development to introduce new technologies and materials often gain a competitive edge.

By evaluating these factors, stakeholders can make informed decisions when selecting slewing ring bearing manufacturers for their specific requirements.

Industry Trends and Outlook

The slewing ring bearing manufacturing industry is experiencing several notable trends and developments that are shaping its future outlook:

Technological Advancements: Rapid advancements in materials science, manufacturing processes, and digitalization are revolutionizing slewing ring bearing production. Innovations such as predictive maintenance, IoT integration, and lightweight materials are enhancing performance and reducing downtime.

Demand for Sustainable Solutions: Growing environmental awareness and regulatory pressures are driving demand for sustainable slewing ring bearing solutions. Manufacturers are increasingly focused on developing eco-friendly materials, energy-efficient designs, and recyclable components to align with sustainability goals.

As the industry continues to evolve, stakeholders must stay abreast of these trends and innovations to capitalize on new opportunities and address emerging challenges in the slewing ring bearing market.

In conclusion, the analysis of the top 15 slewing ring bearing manufacturers underscores their critical role in various industries and applications. Through a meticulous evaluation process, these manufacturers have demonstrated their commitment to excellence, innovation, and customer satisfaction.

Looking ahead, the slewing ring bearing manufacturing industry is poised for continued growth and innovation, driven by technological advancements, sustainability initiatives, and global market expansion. As stakeholders navigate this dynamic landscape, partnering with reputable manufacturers is essential to ensure the success and longevity of their projects and operations.

In summary, the top 15 slewing ring bearing manufacturers represent the pinnacle of quality, reliability, and innovation in the industry, playing a pivotal role in enabling rotational movement and driving progress across various sectors worldwide.